Story Courtesy of the Giant Magellan Telescope Corporation

Texas A&M University and its partners in the Giant Magellan Telescope announced today (Mar. 8) they have awarded IDOM, a renowned engineering and architecture firm based in Spain, a contract to complete the telescope enclosure design by 2024. The award follows an extensive enclosure designer evaluation and selection process based on a detailed set of criteria involving design team experience, proposed approaches to specific design challenges, incorporation of safety management in the design process, and more.

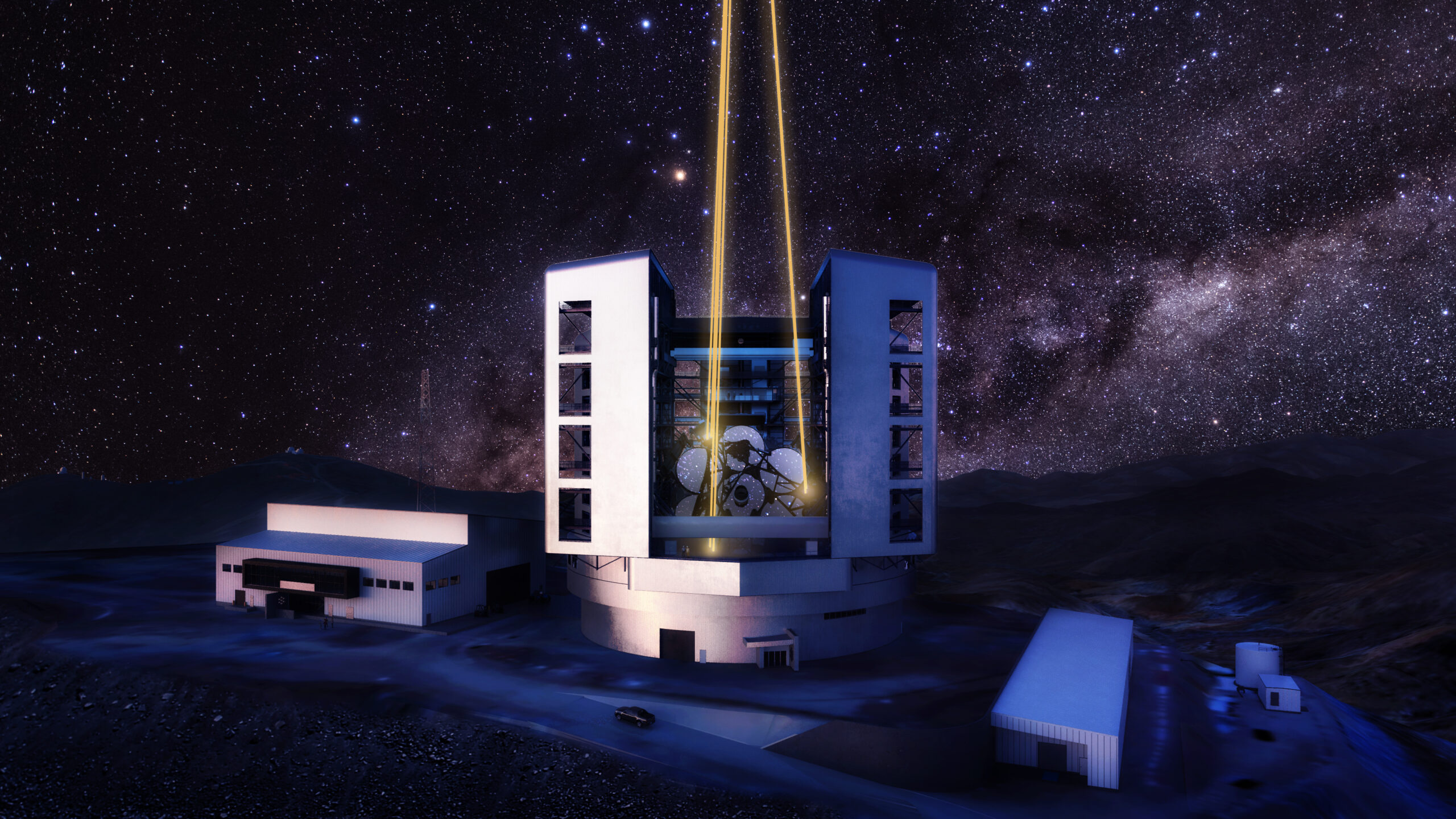

Designing the 4,800 metric ton upper enclosure will be a particularly challenging engineering feat, as it will need to protect the telescope’s giant mirrors from extreme earthquakes and weather, modulate wind speeds and temperatures, and reveal seven of the world’s largest mirrors for unobstructed science observations of the night sky. The enclosure design will also utilize the latest technologies and construction practices to be as sustainable as possible. Once operational in the late 2020s, the Giant Magellan Telescope will produce the sharpest and most detailed images ever taken of our universe — ten times greater than the famed Hubble Space Telescope and four times the James Webb Space Telescope.

“Following an extensive designer evaluation, IDOM proved to have the necessary knowledge, experience, and expertise to solve the design challenges associated with the environmental conditions at the telescope site, especially the local seismic and weather conditions,” said Dr. Bruce Bigelow, the Giant Magellan Telescope’s Site, Enclosure, and Facilities Manager. “Adding the size, functionality, and environmental conditions to the design challenge, efficient manufacturing, especially off-site and modular construction, are key aspects to making the construction of the enclosure safe, reliable and affordable. We’re delighted to work with IDOM to make the enclosure design a reality.”

Headquartered in Bilbao, Spain, IDOM has 45 offices around the world providing global design solutions for a broad portion of the built environment. Leading the enclosure design is IDOM’s Advanced Design and Analysis group. Their engineers develop special and moveable structures, test systems, instruments and facilities for astronomers, nuclear and particle physicists, and other advanced research fields.

”IDOM is proud to be working on this world-class project. Our multi-discipline team of engineers is well positioned to solve both the technical and practical challenges of this complicated machine,” said Tom Lorentz, IDOM’s President of US Operations. “The IDOM team combines world-class design and construction management experience in large and complex movable structures, with first-hand knowledge of civil and site-specific construction practices and capabilities of the local Chilean contractors.” IDOM has made remarkable contributions to the design and construction of astronomical facilities, including the development of components for the Gran Telescopio Canarias, the enclosure and thermal systems for the Daniel K. Inouye Solar Telescope, consulting for the Thirty Meter Telescope, design for the Maunakea Spectroscopic Explorer in which Texas A&M also is a partner, and the conceptual design for the European Extremely Large Telescope.

Designed for Resilience

The Giant Magellan Telescope’s 65-meter-tall enclosure must overcome two key challenges in protecting its giant mirrors — extreme earthquakes and weather. The Giant Magellan Telescope is being constructed at Las Campanas Observatory in the Chilean Atacama Desert, one of the driest deserts and most seismically active regions in the world. Averaging six earthquakes every month, the site will expose the telescope and enclosure to regular seismic events. The enclosure design provides the telescope pier with a seismic isolation system that can survive the strongest earthquakes expected over the 50-year lifetime of the observatory and will allow the telescope to quickly return to operations after the more frequent, but less intense seismic events that are experienced several times per month. The desert’s extreme weather also requires a robust climate control system to keep high winds and temperature changes from impacting the telescope’s giant mirrors and advanced optical technologies. These automated systems are capable of protecting the telescope from daily temperature swings, to provide an optimal observing environment all night long.

“The building design is critical to the scientific use of the telescope,” said Texas A&M astronomer Dr. Darren L. DePoy, who is working to build various instruments and components for the GMT along with fellow astronomers and researchers within the Charles R. ’62 and Judith G. Munnerlyn Astronomical Laboratory. “It must meet stringent requirements to maintain the integrity of the telescope structure in all weather conditions, allow night time viewing of any part of the sky, and allow environmental control of the entire optomechanical system. The best analogy is to imagine a football stadium with a movable roof, but that can also rotate and survive 100 mph winds and serious snow and ice.”

A Focus on Efficiency and Sustainability

Even before the global pandemic created unprecedented supply chain challenges and materials shortages, efficient manufacturing and logistics have remained the priority in the enclosure design process. As such, the enclosure design will use a variety of constructability approaches, utilizing both local materials and a local workforce, to control costs and minimize construction and operational carbon footprints.

IDOM will design the Giant Magellan Telescope’s enclosure to be as sustainable as possible, using the latest technologies and environmental design practices. The construction site currently relies on the Chilean National Electric System, which is predominately supplied by renewable energy. The GMTO Corporation plans to build its own powerline to connect to the Chilean grid, to take advantage of existing renewable energy sources. The completed observatory facilities will employ energy and water efficient technologies, including a greywater treatment and recovery systems to significantly reduce water usage.

IDOM is a privately held, global engineering, architecture, and consulting firm, with more than 4,000 employees and 45 offices around the world, including US locations in Minneapolis and Atlanta and headquarters in Bilbao, Spain. To learn more about IDOM, visit idom.com/en.

The Giant Magellan Telescope project is the work of a distinguished international consortium of leading universities and science institutions. To learn more, visit gmto.org.

For additional information about astronomy at Texas A&M, go to https://physics.tamu.edu/research/astronomy/.

# # # # # # # # # #

About Research at Texas A&M University: As one of the world’s leading research institutions, Texas A&M is at the forefront in making significant contributions to scholarship and discovery, including in science and technology. Research conducted at Texas A&M generated annual expenditures of more than $1.13 billion in fiscal year 2020 and ranked 14th in the National Science Foundation’s Higher Education Research and Development Survey. Texas A&M’s research creates new knowledge that provides basic, fundamental and applied contributions resulting, in many cases, in economic benefits to the state, nation and world. To learn more, visit Research@Texas A&M.